Water Filling Machine

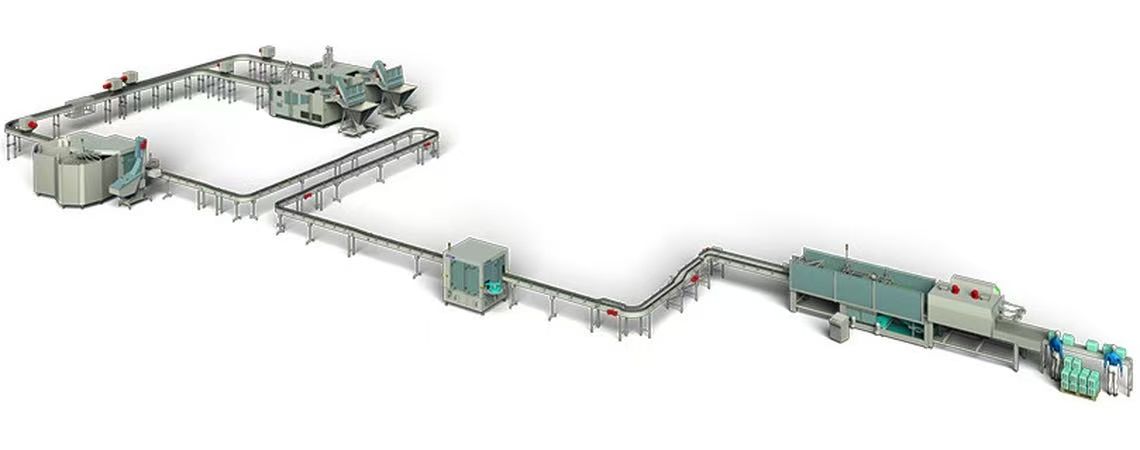

The water filling machine is consists of bottle washing, filling and capping functions. It can used for PET / Glass bottle container. It is used in the requirement of drinking water.

Features

- The main frame of equipment is welded from 120 x 60 x 6mm high-strength carbon steel.

- The main support of the equipment frame is arranged in a "well" type, and the distance between two adjacent supports does not exceed 600mm.

- Using the company's original flipping bottle clamp, the bottle clamp stuck the bottleneck part, to avoid the traditional bottle clamp on the rubber clamp on the bottle thread part of the possible pollution.

- Bottle clamp and lifting mechanism sliding sleeve are made of German igus corrosion resistant maintenance free bearings.

- Filling valve structure design is reasonable, the high speed, high precision. All parts using CNC machining center equipment.

- The sealing head adopts the magnetic constant torque device, when the swivel head is removed through the cover plate, the top cap mold covers the cap, and the cap is straightened to ensure that the cap is positioned correctly in the swivel cover mold to ensure the sealing quality.

Application Fields

Drinking Water Filling Machine is widely used in Mineral Water Factory, Pure Water Plant, Barreled Water Production Line, Bottled Water Production Line and Beverage Factory.

Gallery

- Rinser part of Water filling machine

- Rinser part of Water filling machine

- Filling part of Water filling machine

- Filling part Water filling machine

- Capping part of Water filling machine

- Capping part of Water filling machine

- Youtube

Attached are best selling products in recent time.

Water Filling Machine | Global Supplier of Industrial Liquid Packaging Machines - Hong Guan Machinery

With over 30 years of expertise, Hong Guan Machinery provides Water Filling Machine turnkey solutions for automated filling, capping, labeling, and packing tailored to your liquid production needs.

We serve beverage, food, pharmaceutical, and chemical industries worldwide with energy-efficient and eco-friendly machinery built for speed, precision, and compliance.

Whether you're upgrading an existing line or building a new one, our team ensures seamless integration, long-term reliability, and consistent output.